Taken alongside one another, lyophilization is actually a important Resource for that preservation of biological samples with lots of benefits. We intention to attract notice to your big selection of options offered by freeze drying in pre-medical or primary study.

Is your Labconco product performing appropriately? Product or service Provider is able to help with set up thoughts, troubleshooting and alternative pieces for your personal present Labconco equipment.

Progress in heat transfer: One of several most significant leaps in modern-day freeze-drying is the improvement in heat transfer systems. By optimizing the method and price of heat shipping and delivery on the product, It really is now feasible to keep up item quality while substantially lessening drying situations.

If you wish to carry a complex, lyophilized drug product to market, glimpse no further more when compared to the experts at Particle Sciences.

, a product is to start with brought into a minimal temperature, soon after which almost all the dampness is removed from it.

Coupled with our sterile fill-complete and lyophilization capabilities, we could also carry out particle dimension reduction and complicated formulation things to do under aseptic ailments. Eventually, our analytical and excellent Handle group performs closely with our growth and producing workers to make certain your product is manufactured to the best criteria.

Despite its complexities, improvements in technological know-how and research have mitigated several difficulties, propelling the industry ahead.

These freeze dryers are an all-in-one particular benchtop lyophilizer and stoppering tray dryer that cools to -85°C to freeze dry very low eutectic issue samples.

The vast majority of moisture is removed from the products for the duration of the key drying stage, whilst its construction remains click here optimally intact.

For the reason that water removing process happens less than situations in which the solution remains frozen, it makes certain the integrity and framework with the sample are preserved. It is really a delicate still efficient signifies of extracting humidity devoid of compromising the Organic or chemical attributes of the product or service.

The following step from the process is secondary drying. Secondary drying occurs when the last ice crystal has disappeared, plus the product or service is then cautiously warmed up from its very low temperature. This final dehydration on the item is performed less than a higher-temperature vacuum that rids the technique of any drinking water that did not get more info crystallize and was certain to the products’s molecules.

What will be the strategic great things about dealing with a deal improvement and producing companion (CDMO) lover which includes in depth lyophilization working experience?

The information of our Site is always obtainable in English and partly in other languages. Select your most popular language and we will teach you the information in that language, if obtainable.

Lyophilization or freeze-drying has benefits, from greater shelf life and improved security to high-quality meals products. With numerous applications of this intricate nonetheless highly advantageous know-how in a variety of industries — pharmaceutical, food stuff processing, dairy, plus much more — lyophilization is right here to remain.

Devin Ratray Then & Now!

Devin Ratray Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Michelle Pfeiffer Then & Now!

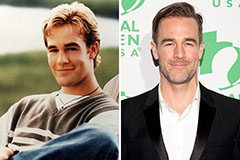

Michelle Pfeiffer Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now!